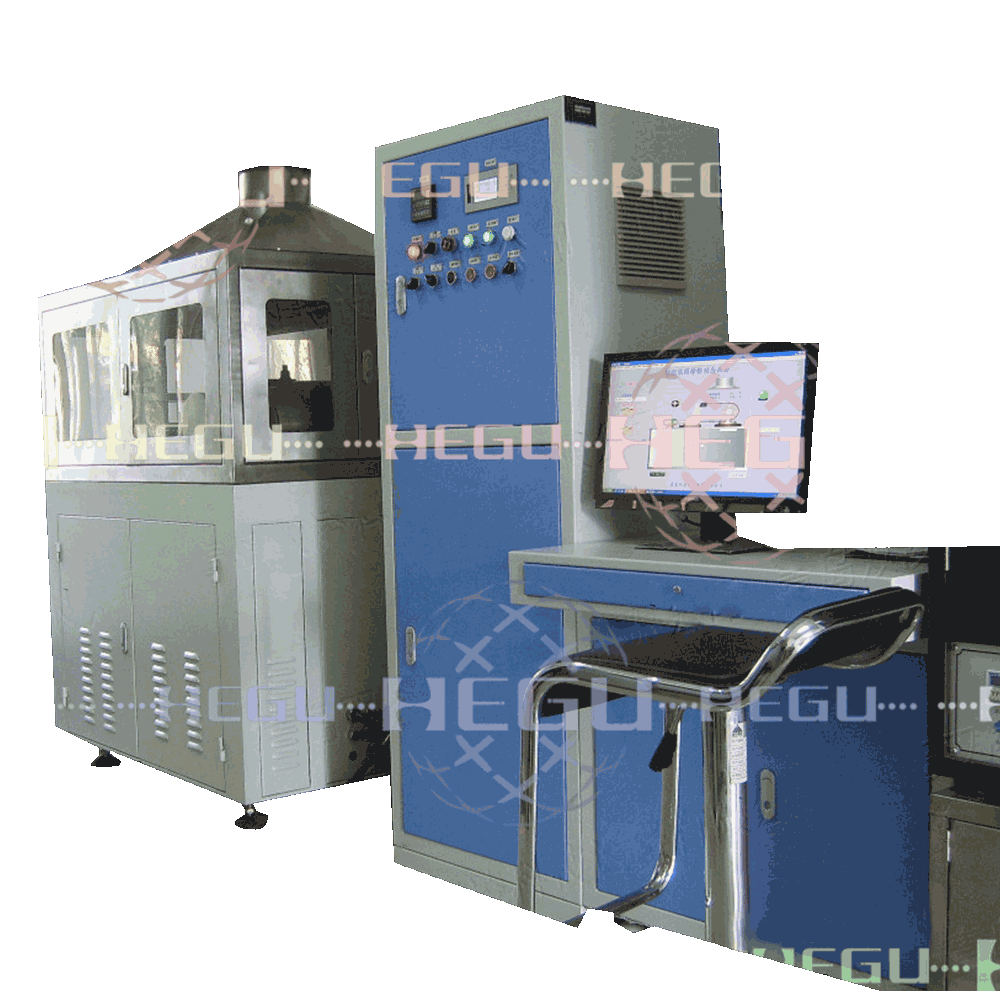

SGM-02B Conveyor belt intelligent drum friction tester

Introduction :

Conveyor belt intelligent drum friction tester, Accord with GB/T7986–2013 “Conveyor belts-Drum friction-Method of test”standard and MT450-1995, MT914-2008 other test relevant standards and operating requirements. The machine is suitable for fabric core flame retardant conveyor belt and other fire-retardant conveyor belt drum friction experiment. The tester have intelligent adjust tension device, change in the past time lever tension device during the test process ,as the friction force extension tension is not constant and weight tension device operate complex problems. Truly realize whole experiment totally-enclosed intelligent control.The user should take standard management,make sure test result reliability and continuity.

Technical data:

The engine power |

11.5 KW |

The power supply |

AC380V 50HZ three-phase five-wire system |

Drum motor power |

11KW |

Drum material |

45# steel, nitriding treatment |

Drum load speed |

200 + / – 5 r/min |

Miniature blower |

Power: 220V, 25W |

Blowing wind speed |

2.0 + / – 0.1 m/s; The air flow is adjustable |

Porous pipe diameter: Φ40 (inner diameter), the inner diameter of the vent hole 6mm 21, spacing 13mmDistance between porous tube and drum: 600mm |

|

The weight of the |

1200kg |

size |

Mechanical cabinet 1400*860*1900mm Electrical control cabinet 1500*760*1700mm |

Shgara tightening force |

The servo system automatically applies tightening force with the range of 343N-2000N, not exceeding 2000N, and automatically detects belt break |

Range of test time recording |

99 hours, 60 minutes and 60 seconds, the digital display is adjustable, the set time parameter value reaches the automatic stop. |

Temperature measurement range |

Automatic overtemperature detection at room temperature -400°C and stop, temperature measurement accuracy: ±1°C |

Temperature intelligent instrument display, and can print temperature curve. |

|

Temperature sensor |

Three, (one for use and two for spare) |

113-1.png)