HEGU Machines

Recent Work

SLGQ-70 Steel cord conveyor belt cutting machinery

SLGQ-70 steel cord conveyor belt cutting machinery is our company design for conveyor belt manufacturers、conveyor belt use factory、laboratory making the test sample, it is adapted for steel cord conveyor belt、PVG、PVC making sample. The instrument simplicity of operation, reduce testers work strength, save making time, no dust pollution, improve work efficiency, it’s the ideal sample preparation machine. Technical data: Power voltage 220V/380V Max. shear force 642KN Working pressure speed 70Mpa Cutting thickness ≤35mm Cutting length Unlimited(depend on the width

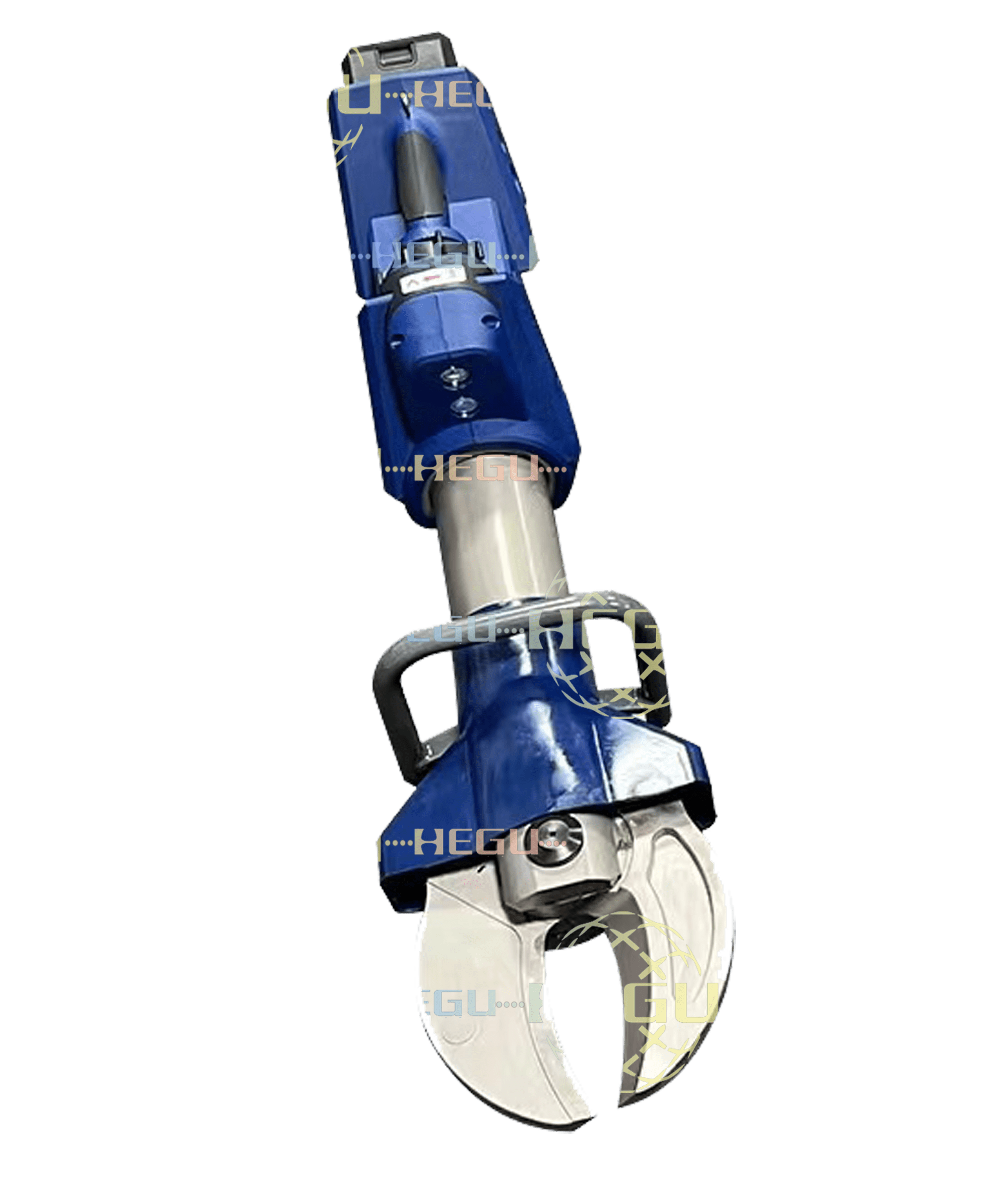

SLGQ-72E Steel cord conveyor belt cutting machinery

SLGQ-72E steel cord conveyor belt cutting machinery is our company design for conveyor belt manufacturers、conveyor belt use factory、laboratory making the test sample, it is adapted for steel cord conveyor belt、PVG、PVC making sample. The instrument simplicity of operation, reduce testers work strength, save making time, no dust pollution, improve work efficiency, it’s the ideal sample preparation machine. Technical data: Power voltage 28V Motor power 454W Working pressure speed 72Mpa Max. shear force 642KN Cutting thickness ≤35mm Cutting length Unlimited(depend

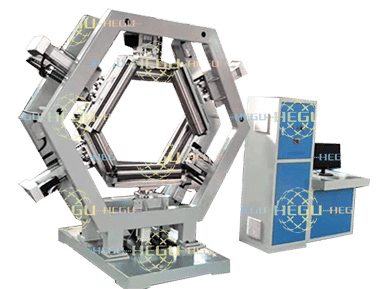

SLGDQ-700/500Dynamic bending fatigue testing machine for tubular belt

At present, the use requirements and service life of the tubular belt used by the tubular belt conveyor at home and abroad are increasing year by year. The technical parameters in the real sense of the product remain in the requirements of appearance, width, length, strength, climbing angle and turning angle. On the premise of avoiding pipe collapse and saving power consumption during use, the production process, skeleton material,

SLGZ-700-660 tubular conveyor belt tester

The resilience index of the conveyor belt of the circular tube belt conveyor has a great impact on the pipe forming performance, running resistance and wear of the conveyor belt, and is one of the unique indexes of the special conveyor and conveyor belt of the circular tube belt conveyor. This instrument and test method are set up for this purpose. Technical data: Nominal pipe

Rubber machinery open rubber mixer and closed rubber mixer

General rubber machinery is the machinery for preparing rubber raw materials or semi-finished products, including raw material processing machinery, rubber mixing machine, extruder, calender, cord pretreatment device and slitter. Rubber mixing machine Rubber mixing machine is divided into two categories, namely, separate type and closed type. Open type rubber mixer

Testing machine definition and classification

Testing machine definition and classification Mechanical properties and process properties of materials, parts and components testing machine Instruments and equipment for material testing machine. Testing machine includes: metal material testing machine, non-metallic material testing machine, process testing machine, force measuring (torque) machine, balancing machine, shaking table, non-destructive testing instrument,

Two test methods of rubber low temperature brittleness tester

One, rubber test equipment aging performance test method 1, hot air aging test under the action of atmospheric pressure, constant temperature and hot air, after a certain time, measure the change of physical and mechanical properties of the sample, used to measure the thermal stability of rubber and the performance

Tensile testing machine introduction and characteristics

Tensile testing machine is mainly suitable for plastic film, adhesive, adhesive tape, adhesive, medical patch, release paper, protective film, combination cover, backplane materials, non-woven fabric, rubber, paper fiber and other products of tensile, peeling, deformation, tear, heat sealing, bonding, puncture force and other performance test. Tensile testing machine is also

113-1.png)