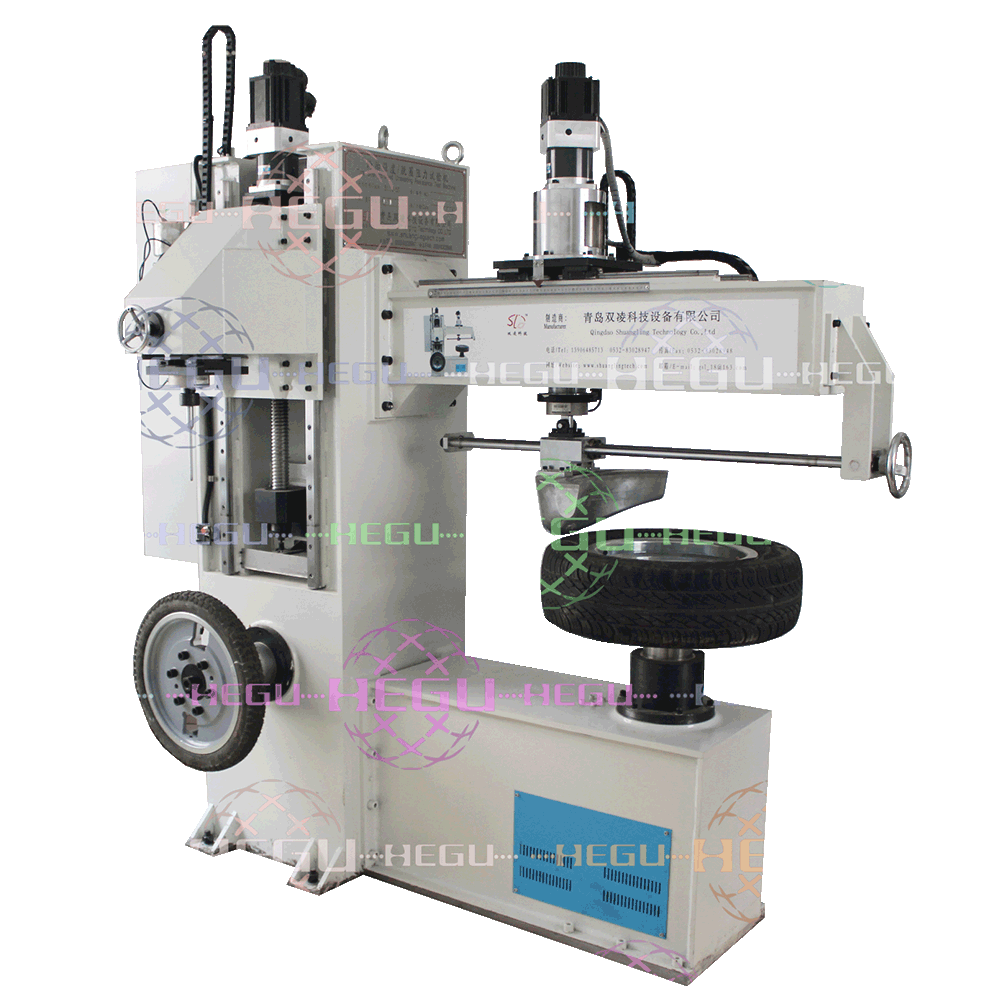

SLLQ-50 Tire strength / bead unseating tester

overview :

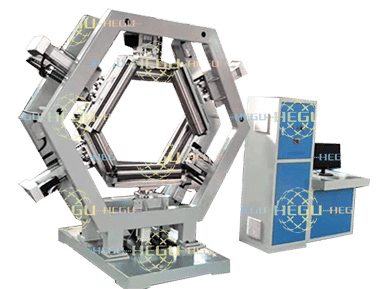

According to GB / T4502-2009 and GB / T13203-2007standard, combined with the accuracy and repeatability requirements, the product is simplicity of operation, compact equipment, long service life, the design principles of continuous operation ,whole machine combine with the electric and mechanical transmission,steel skeleton structure, can be based on a variety of different rims replace any sample .Electric by primary instrument,drive distribution element ,actuators, computers, PLC, printer, etc., through combination of the above devices, finish collection and save data.for humanization design.. The product – tire strength / bead unseating resistance tester according to GB / T4502 standard 5.1 and 5.2 bead unseating resistance and strength test, GB / T13203-2007 standard 5.1 strength test methods and test requirements.

Technical data:

Strength test of motorcycle tires:

Device structure |

Vertical Rack |

Ram return speed |

50~500mm/min (configurable) |

Diameter of the tire |

300-800mm |

Load measurement accuracy |

±1‰ |

Maximum section width of the tire |

<250mm |

Displacement accuracy |

±1% |

Tire rim nominal diameter |

8"~21" |

Head Diameter |

8mm±0.6mm |

Loading |

Mechanical servo loading |

Motor |

Delta servo motor 1.5Kw |

Strength test load |

Max.20KN |

Equipment size |

1900 mm long * 700mm wide * 2300mm high |

Test load speed |

50±2.5mm/min(can be set to an accuracy of ± 0.1mm / min) |

Total weight |

About 1.7 t |

Car tire strength, unseating test:

Device structure |

Vertical Rack |

Ram return speed |

50~500mm/min (configurable) |

Diameter of the tire |

450-1000mm |

Load measurement accuracy |

±1‰ |

Maximum section width of the tire |

<400mm |

Displacement accuracy |

±1% |

Tire rim nominal diameter |

10"~28" |

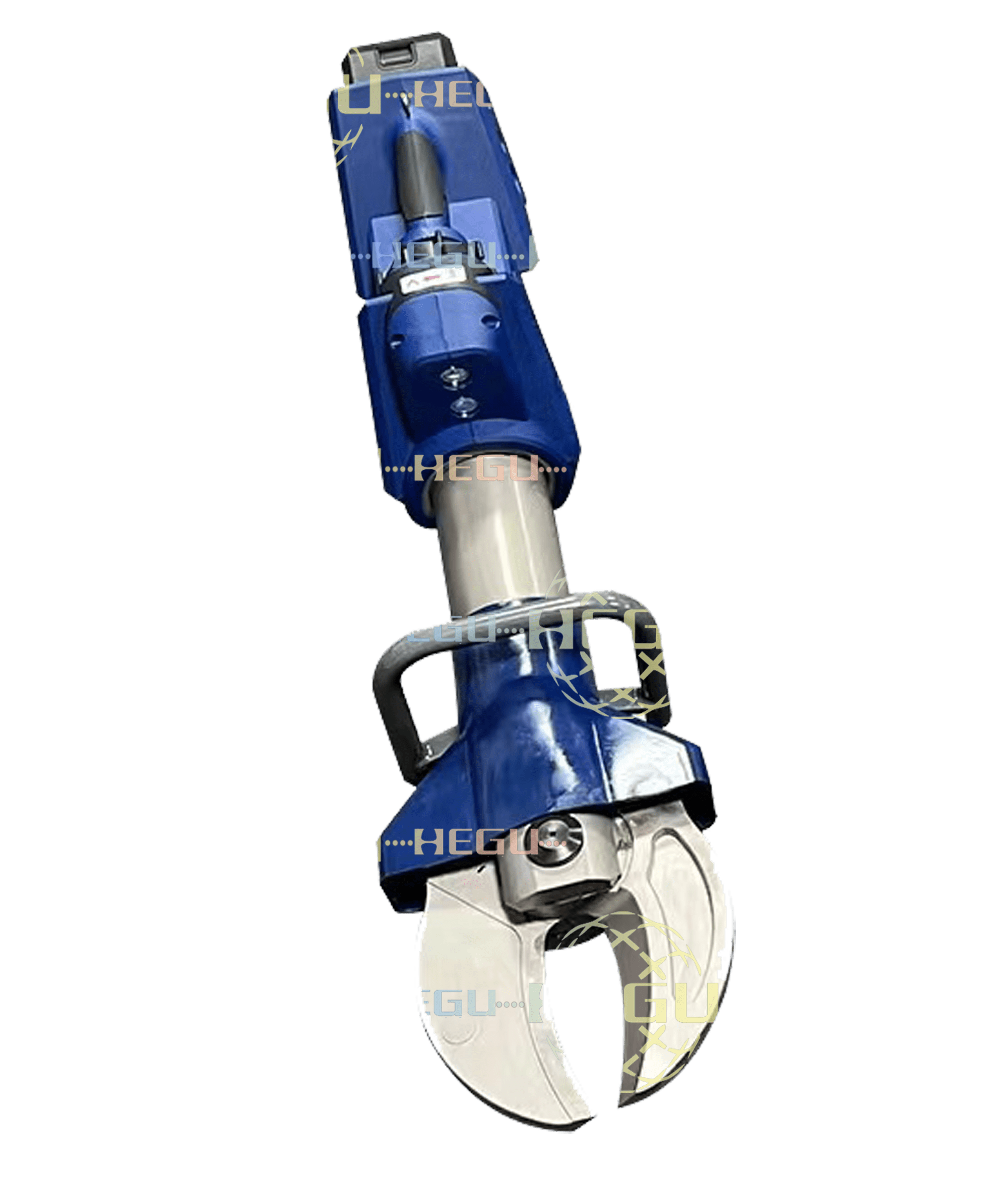

Head Diameter |

19mm±0.5mm |

Loading |

Mechanical servo loading |

Motor |

Servo motor power 2.25Kw |

Strength test load |

Max.50KN,Unseating resistance load,Max.20KN |

Equipment size |

1900 mm long * 700mm wide * 2300mm high |

Test load speed |

50±2.5mm/min(can be set to an accuracy of ± 0.1mm / min) |

Total weight |

About 1.7 t |

113-1.png)