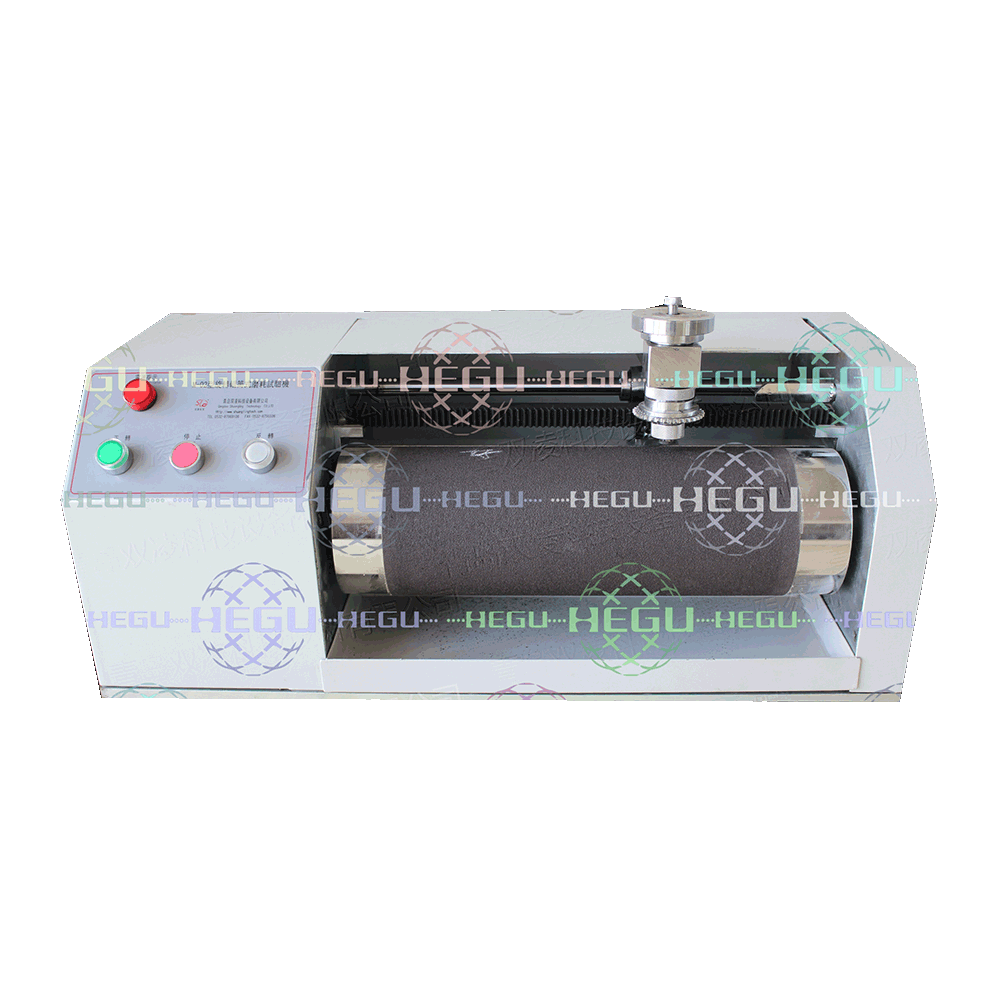

XM-02 Rotating drum abrasion testing machine

overview:

In many tests of rubber products, wear test is an indispensable test. For many rubber products, the wear performance is directly related to its service life, practical significance is great, is one of the most important technical indicators. Therefore, the test of wear performance is a very important problem in rubber industry. For many years, the instruments used in testing rubber wear test performance in our country are Akron wear testing machine and Grassili wear testing machine, etc. Although the two kinds of wear testing machine can determine rubber wear performance, but there are some shortcomings such as too long test period and repeated test route. XM-02 rotary roller abrasive machine is according to the international ISO4649-2002 and according to GB9867-2008 and the introduction of German Zwick abrasive testing machine for development. Compared with Akron abrasion testing machine and Grassili abrasion testing machine, this machine has the advantages of small sample required, short test period and no repetition of friction path, so it is more popular and universal in the world at present.

characteristic:

- Sand paper imported from Japan, with stable quality and high precision.

- The roller and the gripper feed device have high processing accuracy to ensure the accuracy of the test data.

- Damable parts are standard parts, free customers from subsequent maintenance distress, easy to replace and repair.

- After the end of the test, the gripper has automatic return function, without manual operation to return

Technical data:

roller diameter |

150±0.2mm |

Traverse velocity of diameter specimen holder |

4.2±0.04r/mm |

roller length |

500mm |

Grinding stroke length |

20m±0.1 m or 40m±0.2 m |

Length of emery cloth |

474mm±1mm |

Sample rotation speed |

9 R / min or no rotation |

roller |

40±1r/min |

output power |

110W |

diameter |

sixteen ± 2 mm, height not less than 6 mm |

motor speed |

115r/min |

The rotation speed of the sample can be adjusted to its weight |

5N ± 0.1 N、10N ± 0.2 n (5N for itself, and 10N for additional 5N weight) |

||

113-1.png)