HEGU Machines

Recent Work

XSYM-02 High pressure hose hydraulic impluse without flexing test machine

XSYM-02 High pressure hose hydraulic impluse without flexing test machine overview : XSYM-02 High pressure hose hydraulic impluse without flexing test machine in accordance to GB/T5568-2006/ISO6803:1994 standard, which is a standard device for test rubber, or plastic hose and hose assemblies. Impulse test and pressure test for high pressure hydraulic hose and hose assemblies, which are subjected to pulsed pressure in use. Technical data: Maximum

XSDW-01 Rubber and plastic hose dynamic bend fatigue strength tester

XSDW-01 Rubber and plastic hose dynamic bend fatigue strength tester overview : According to HG/T 3037-2008 H appendix HG/T (normative appendix), test method of bend fatigue strength is composed of the following components: (1) The test apparatus shall be in accordance with the test of various specifications of the hose assemblies that can be assembled in Table 1. (2) The test device should configure with a GB/T-1690 liquid C charging device (3) A counting device for a combination

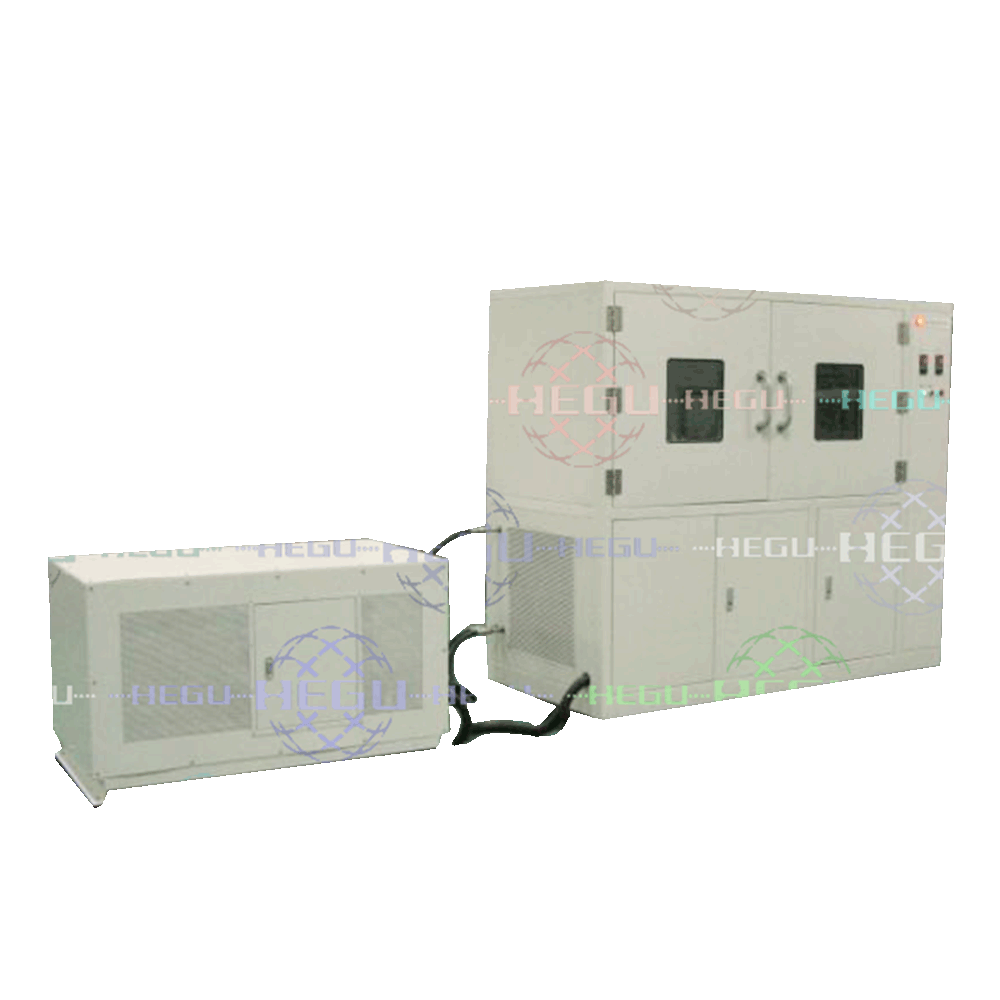

XSPR-01A Rubber hose flammability test device

XSPR-01A Rubber hose flammability test device Overview: XSPR-01A Rubber hose flammability test device suitable for research institute and factory in laboratory condition,inter diameter below50mm(include 50mm)hose (Not include the hoses reserve use for internal combustion engine oil fuel)inflammability report test,products suitable for GB/T15907-2008/ISO8030:1995”Rubber and plastics hoses—Method of test for flammability” using requirement. Component: 1.Reagent, 10ml measurement and 1000ml reagent containers, alcohol lamp 2.Electronic control system 3.The mechanical part of the specimen fixture, alcohol lamp, bracket and box Test equipment see figure

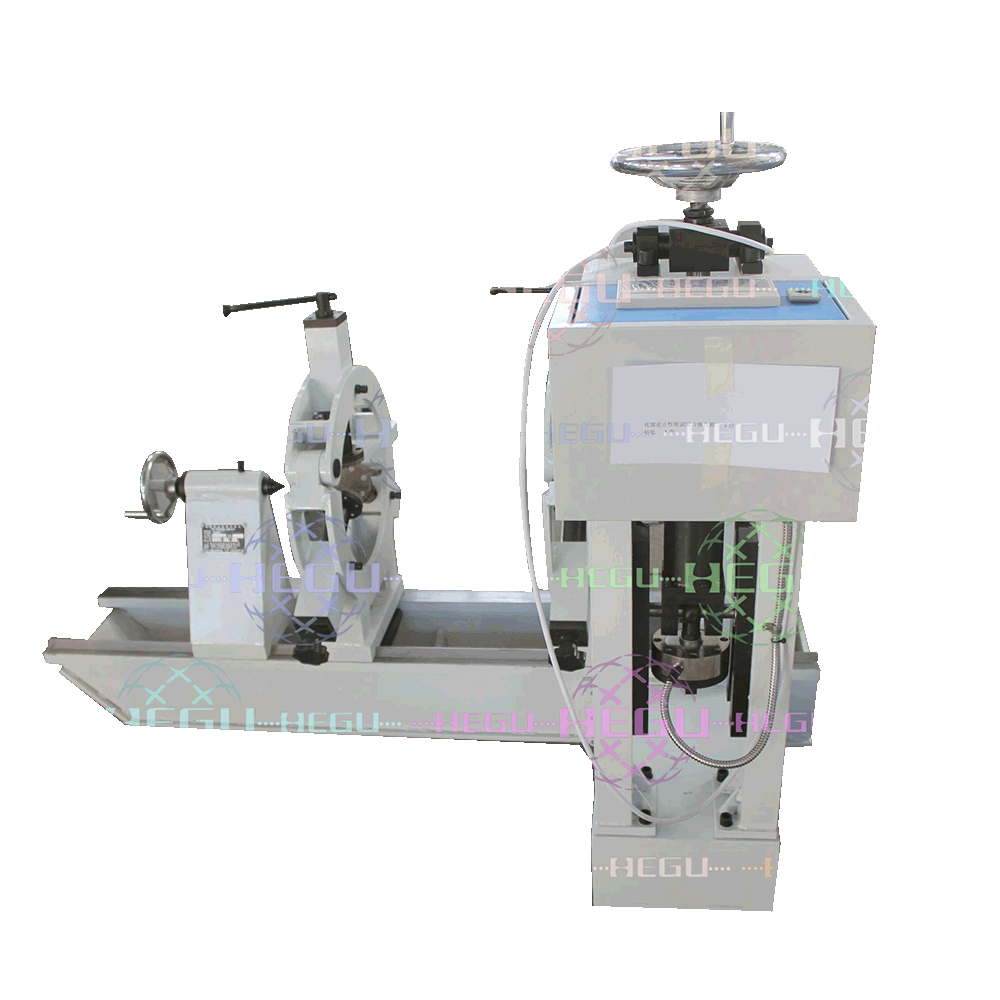

TG-NZ Roller Reverse Stop Performance Testing Machine(Computer controlled)

TG-NZ Roller Reverse Stop Performance Testing Machine(Computer controlled) overview: TG-NZ roller reverse stop performance machine control by computer,the reverse stop performance of roller is detected when a certain rotation force is applied to the rollers.The instrument is suitable for Coal mine belt conveyor roller technical requirements standard of operation requirement.The instrument is suitable for the scientific research institutions ,the conveying machine manufacturers, the quality inspection institutions and other units.

113-1.png)